MANUFACTURING CAPABILITIES

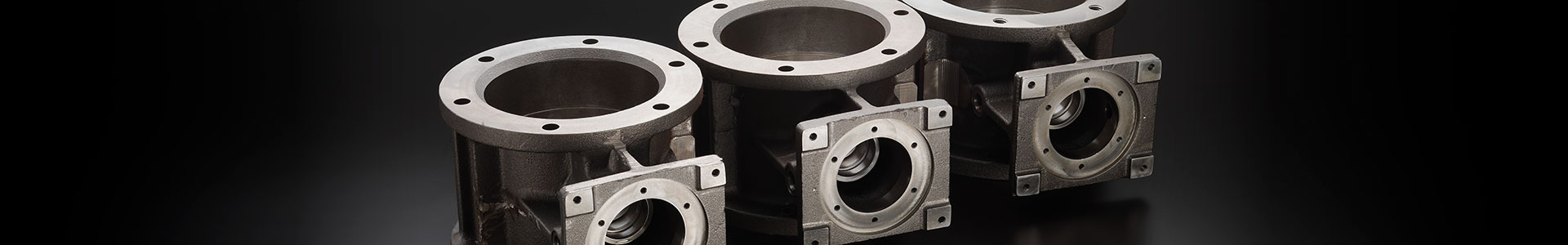

QCC has been a leader in precision components machining for more than 60 years. Our manufacturing capabilities incorporate technologies across a broad base of advanced processes. Our machining includes turning, milling, grinding, diamond bore-sizing and other techniques. We take on the most challenging projects, providing Design for Manufacturability services so that we can take your part from concept to a successful PPAP quickly and cost effectively.

QCC’s cellular work-center arrangement allows us to operate in a Lean manufacturing single-piece flow manner where raw materials enter the cell and exit as finished, washed and packed parts. QCC’s Quality Management Systems are AS9100-D certified. Our facilities offer 130,000 square feet of production space and utilize more than 100 major CNC machining assets and 200 pieces of ancillary manufacturing equipment.

QCC can meet your precision machining needs across a wide range of materials including aluminum, ductile and gray iron, alloy steel and stainless steel. Plus, our in-house tool room designs and builds custom work holding for forgings and castings. Our manufacturing processes meet the stringent cleanliness requirements of the diesel fuel systems and fluid power industries.

- Prototype to Production Manufacturing Lot Quantities

- DFM Engineering Support

- Global Material & Foundry Sourcing

- Assembly-Ready Components Door to Floor

- AS9100-D Quality Management Systems Certified